Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

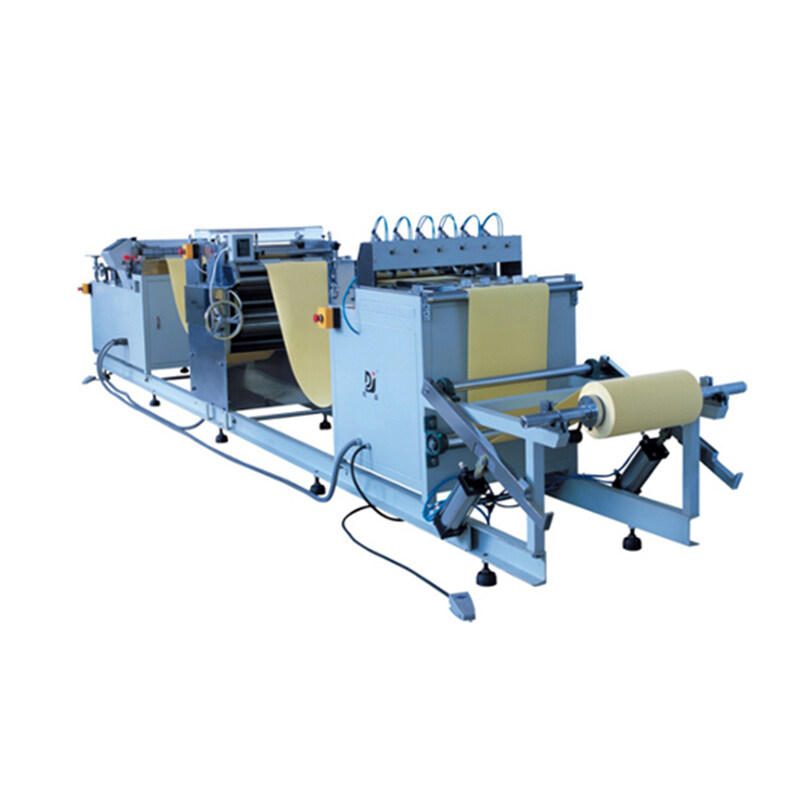

SEYG-650-3R Separated Glass Fiber Pleating Machine

The SEYG-650-3R separated glass fiber pleating machine is a high-quality device used for pleating fiberglass. It is equipped with advanced technology and high-quality components to ensure efficient and safe production. This machine is designed to meet the needs of various industries, including protective panels, thermal insulation panels, and more.

-

Product Details

Product Introduction

This separator glass fiber pleating machine features a powerful motor and a precise control system that ensures precise pleating with consistent results. The machine also has a large pleating area, allowing for a high output of pleats in a short amount of time. This machine is perfect for any industry that needs to produce high-quality pleats with separated glass fiber. It is reliable, durable, and easy to use, making it an excellent choice for any business.

Specification

1. Production speed: 10m/min

2. Pleating height: 120mm; 190mm, 260mm (or customized)

3. Max paper width: 650mm

4. Motor power: 1.1Kw

5. Power supply: 220V/50Hz

6. Machine weight: 500Kg

7. Machine size: 1800mm*1200mm*1300mm (L*W*H)

Features of Separated Glass Fiber Pleating Machine

1. Automatic paper feeding device for easy operation.

2. Three sets of rollers that are easy to replace and can accommodate various pleating heights.

3. Roller surface has rubber sheets to prevent glass fiber from breaking during pleating.

4. Equipped with a frequency converter for different working conditions.

5. Fast production speed, low noise, and easy operation.

6. Can pleat fiberglass of different heights into any shape according to your requirements.

Advantages of Separated Glass Fiber Pleating Machine

1.High production efficiency and speed of 10m/min:

With a speed of 10m/min, this machine can produce a large number of folds in a short time, making it ideal for high-volume production.

2.Designed to accommodate different paper widths:

Paper width can be adjusted from 650mm to 2200mm, depending on your requirement,you can adjust the paper width to meet your specific production needs.

3.Various high-quality shock absorption systems are used to ensure product quality:

The machine is equipped with various high-quality shock absorption systems that ensure product quality. These systems absorb shock and vibration during the pleating process, ensuring that the fiberglass is pleated evenly and without damage.

4.Equipped with a self-monitoring device:

The machine is equipped with a self-monitoring device that records line breaks and automatically shuts down production for safety. This feature ensures that the machine operates safely and efficiently, minimizing the risk of accidents and downtime.